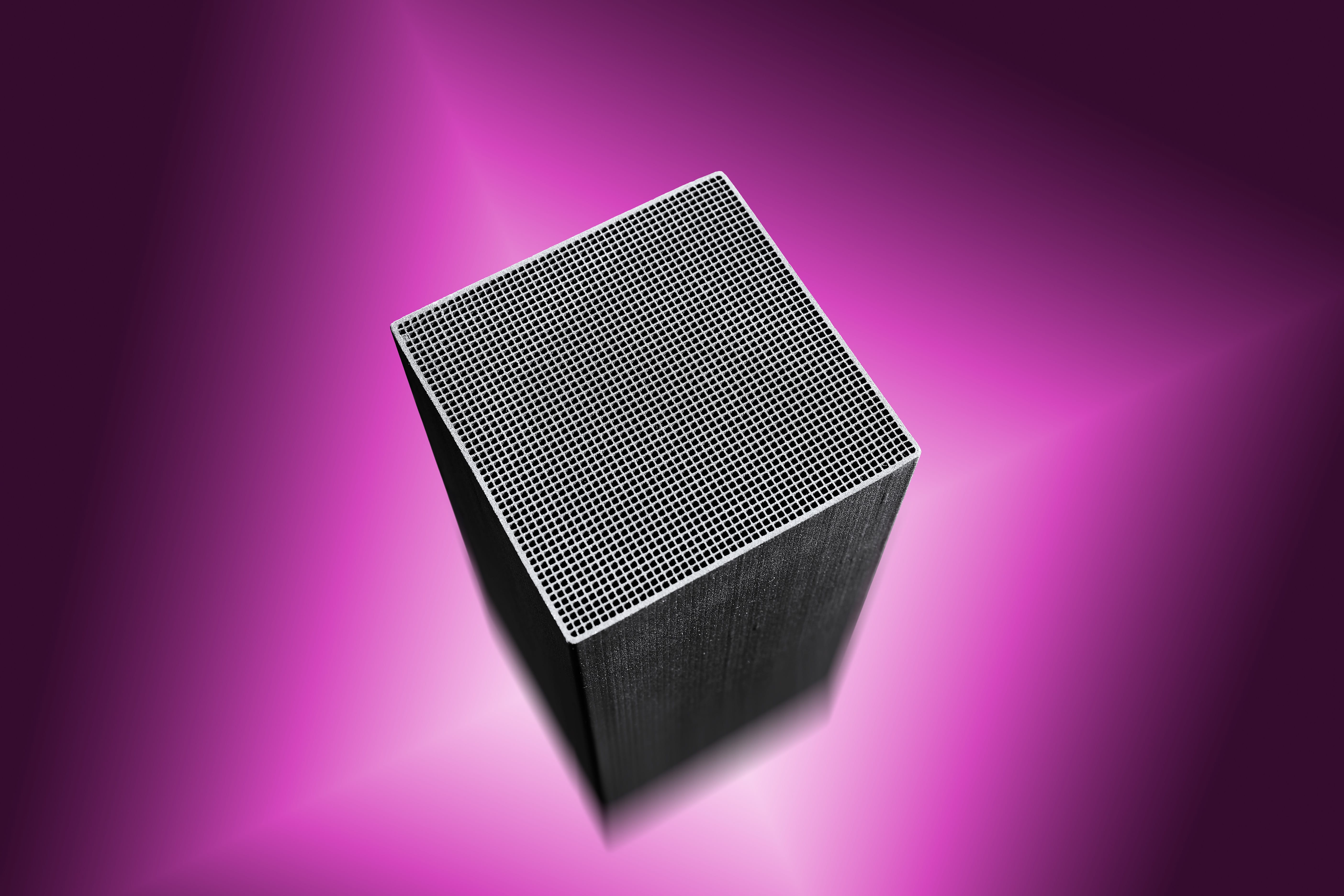

Binder jetting is the most commonly used process in the additive manufacturing of ceramics. Binder jetting enables the cost-effective production of complex SiC components, especially in small quantities. Compared to conventional ceramic forming processes, SiC powder has to meet new requirements to achieve excellent material properties in the additive manufactured part. ESK-SIC developed the E-COMPACTSIC powder especially for binder jetting and other powder-bed based production processes. Thanks to the special properties, such as

- high flow rate

- high bulk density

the powder is suited for powder-bed based additive manufacturing processes. Powders with varying particle size distributions are provided depending on the specific application (layer thickness, resolution of the printing process, etc.).