Thanks to its cumulative properties, SiC has become one of the most important raw materials for the ceramics and refractories industry.

These “carbide ceramics“ are materials on the basis of silicon carbide and are produced in different variants depending on the intended application. They all exhibit the typical properties of silicon carbide.

These typical properties have different effects in the material variants:

- silicate-bonded silicon carbide

- recrystallized silicon carbide (RSiC)

- nitride- or oxynitride-bonded silicon carbide (NSiC)

- Reaction-bonded silicon-infiltrated silicon carbide (SiSiC)

- sintered silicon carbide (SSiC)

- liquid-phase-sintered silicon carbide (LPS-SiC)

Type and percentage of the bond types are crucial for the specific characteristic properties of the silicon carbide ceramics.

They are used in kiln furniture, e.g. beams, rollers, batts.

Apart from our standard grades for abrasives and refractories, special fine sizes are used.

ESK-SiC for bricks / monolithics / crucibles

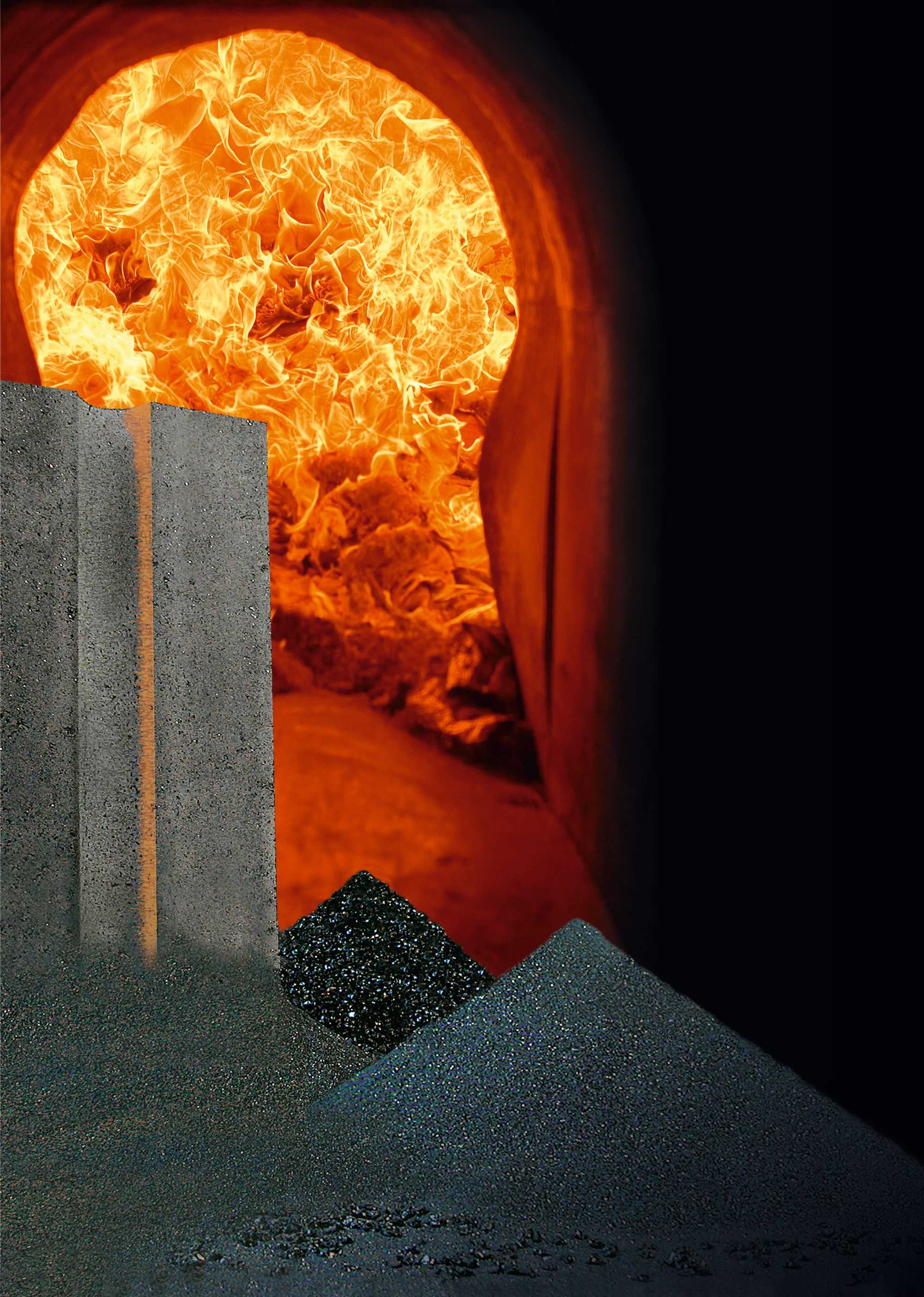

SiC is especially suitable for the production of crucibles, kiln linings and muffle kilns thanks to its high thermal conductivity and low thermal expansion, combined with excellent chemical resistance.

SiC filters for metal casting led to a quantum leap in quality and yield in foundry systems.

▶ Material data sheet E-REFSIC 98

▶ Material data sheet E-REFSIC 95